FOR PROFESSIONAL USE ONLY

Reference the floor covering and adhesive manufacturers documentation to verify suitability of Platform L3 as a subfloor for the flooring system (any adhesive used for concrete is generally suitable for L3). Follow the directions of the flooring and adhesive manufacturer to determine the maximum allowable moisture content (RH) or Moisture Vapor Emission Rate (MVER) of the substrate. If the moisture content (ASTM F-2170) or Moisture Vapor Emission Rate (MVER) (ASTM F-1869) of the substrate exceeds the requirements of the flooring system, utilize an approved 100% epoxy moisture vapor mitigator prior to installation of the Platform L3.

Honor all moving joints. Complete crack and substrate repairs prior to installation. Consult an engineer for required joints and crack repairs prior to installation. Contact Technical Services for required surface preparation on installations that will be exposed to high rolling loads or high point loads.

Maintain a minimum of 50ºF during the pour and for 72 hours after the pour. Acclimate the material to a minimum of 50ºF prior to mixing. To maximize flowability and working time, utilize cool water when temperatures exceed 85ºF.

For installation over hydronic heating systems utilize a minimum of 1.5” of material, with ¾” of material above the hydronic system. Platform L3 is compatible with and accepts the direct application of, urethane, moisture cure and other typical floor covering adhesives.

Platform L3 can be applied to a maximum depth of 2” NEAT monolithically, and 3” NEAT in isolated areas.

Extension: Extend L3 with aggregate in larger areas that exceed 2”, and in all applications deeper than 3”. When extending, utilize up to 50% by weight (25 lbs pea gravel per 50 lb bag) 1/4” - 3/8” clean, washed and surface saturated dry (SSD) pea gravel. Ensure pea gravel is thoroughly mixed in (encapsulated) by the L3. Contact Technical services for details.

Multiple Lifts: When installing multiple lifts of L3, wait for the first lift to dry adequately (see table) and prime with P360.

Surface Preparation

All Substrates must be sound, clean, dry and free of contaminants (oil, dirt, laitance etc.) that may interfere with adhesion. Areas of the floor that do not exhibit a tensile pull strength greater than 100 psi are not suitable and must be mechanically removed to a sound, stable base and subsequently repaired prior to application of Platform L3. Do not use solvents, acids or chemical adhesive removers to prepare the substrate. All bond breaking substances (cure residues, excess salts from silicates etc.) must be removed prior to priming. Completely vacuum all dust and debris from the substrate prior to priming with designated Platform Primer P360.

Gypsum substrates must exhibit a sound surface, be free from dust and surface weakness prior to application of the primer.

Non-soluble adhesives must be scraped to a well bonded residue. Water soluble adhesives must be removed mechanically from the substrate. Verify type of adhesive prior to mechanical removal to ensure adhesive containing asbestos is not introduced into the environment. Follow all local, state and federal laws for removal and disposal of adhesive or flooring materials containing asbestos. Platform L3 is not for use as a suitable means to encapsulate residue of hazardous materials.

Wood floors must satisfy local building codes, utilize exterior grade plywood, suitable OSB or other resistant to water. Due to the high material strength of L3 special care and attention must be given to ensure deflection of wood does not exceed L/720. The wood must be free of contaminants (oils, wax, dirt etc.) that could function as bond breaker prior to application of the primer. Wood substrates typically require lath when using high strength materials like L3, contact technical support for details.

Substrate Priming

Prime properly prepared substrate with Platform Primer P360 prior to the application of L3. Carefully read Primer data sheet to ENSURE Primer is utilized diluted (porous substrates) or undiluted (non-porous substrates) per given substrate.

Platform L3 is very flowable and will flow through any open voids. To avoid material flow in undesirable areas, seal voids or penetrations with a rapid setting patch or expanding foam.

Prime wood subfloors with two applications of P360 NEAT, and install reinforcing lath after priming. Turn HVAC units off for installation and the first 16-24 hours of material cure. Maintain air circulation to assist in drying, however avoid airflow across the surface of the material for 16-24 hours. Avoid direct exposure to direct sun during the application.

Mixing

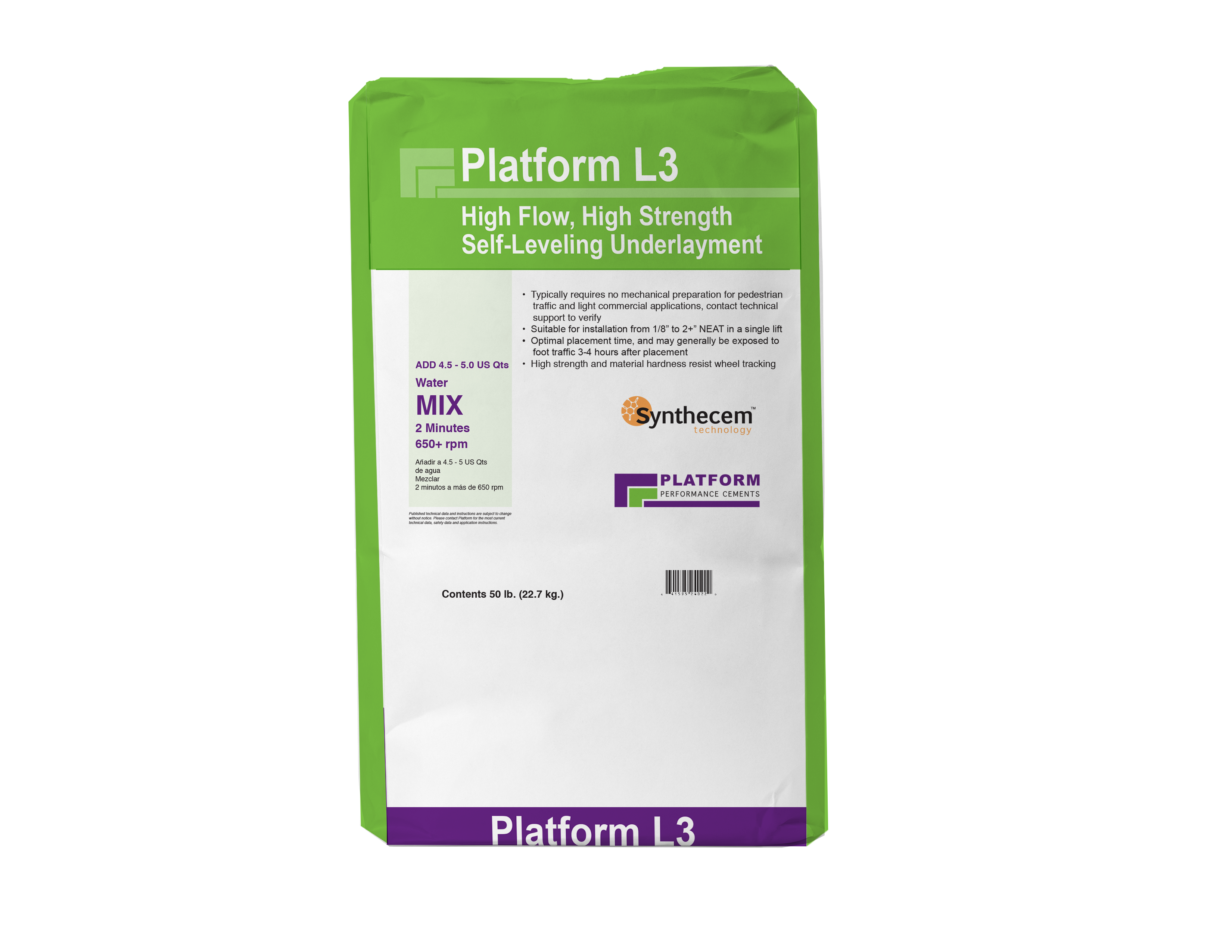

Water: 4.5 - 5 US Qts (4.25 - 4.73 L) per 50 lbs (22.7 kg)

Mix Time: 2 minutes with minimum 650 rpm drill or through approved mixer/pump.

Over-watering and/or under mixing (failing to generate adequate shear) will result in lower ultimate compressive strengths.

Add designated clean, potable water to a clean mixing barrel, add the powder and mix at the designated speed for 2 minutes. Ensure all material is homogenous, and no dry lumps or unmixed material is at the bottom of the mixing barrel. During mixing, keep the paddle below the surface of the material to reduce introduction of excess air into the mix. Once mixed, immediately pour onto the substrate to maximize material flow and placement time.

Pumping

Platform L3 may be mixed and/or pumped with most standard batch or inline mixing/pumping equipment. Contact Platform Technical services for pump questions.

Material Application

Immediately after mixing is complete, pour the mix on the substrate, rake to the required depth and smooth using appropriate tools (smoother or porcupine roller). When placing mixed material, maintain a wet edge, always pouring back into the leading edge of the previous placement.

Drying Time

Do not used forced air to assist in drying Platform L3, but do provide for adequate ventilation and circulation of air. Platform L3 generally hardens to accept light foot traffic 3 - 4 hours after placement. Avoid construction traffic for a minimum of 12 - 16 hours (temperature dependent).

L3 is self drying, do not wet cure or use curing or sealing compounds. To facilitate drying, ensure rooms where L3 is installed have air circulation. Do not introduce heavy airflow to the surface of L3 until after 16-24 hours of drying. Temperature, humidity and airflow will impact drying time. The use of a moisture meter is recommended to verify readiness for flooring. Multiple areas should be surveyed to ensure dryness throughout. Use of a Delmhorst BD-2100 or G-79 in gypsum scale with a reading of 5% or lower, or a GE Protimeter Aquant in RF (Radio Frequency) mode with a reading of 180 or lower, indicates suitable dryness for virtually any floor covering.

General drying guidelines assuming ambient temps of 70ºF with air circulation (Cooler temperatures and/or high humidity will increase drying times);

Breathable Flooring Systems

Depth Dry time required before installing flooring

0 - 1” 16 hours (next day)

1 - 2” 36 hours (1.5 days)

2 - 3” 60 hours (2.5 days)

Non-Breathable/Impervious Flooring Systems

Depth Dry time required before installing flooring

0 - 1/2” 24 hours

1/2 - 1” 48 hours

>1” 48 hours plus 36 hours for each additional 1/2’

Internal testing of the latest generation of high performance underlayments including L3 indicates bond of cementitious adhesives like thinset and patch is significantly enhanced with the use of a primer. When utilizing cementitious patch or setting materials (thinset) enhanced bond can be realized by priming dried L3 with P360 primer diluted at 3:1 (water:primer). For enhanced bond and resistance to the movement of moisture and alkalinity prime the L3 with P360 diluted 1:1..